Knipex Automatic Wire Stripper 12 12 02

Knipex Automatic Wire Stripper 12 12 02

Review: Knipex Automatic Wire Stripper 12 12 02

ipsum

Knipex Automatic Wire Stripper 12 12 02 Overview

- Two pairs of blades cut parallel into the insulation and remove it with a separating movement.

- Wire stripping capacities 0.03-0.09 / 0.14 / 0.38 / 0.57 / 1.0 / 1.5 / 2.08 mm², AWG 32 – 14

- Handles with multi-component grips

- Length stop that can be easily adjusted by pressing and sliding for accurately repeated wire stripping

- Spare set of blade available

- Net weight 447 g

Knipex Automatic Wire Stripper 12 12 02

- Length stop and cable routing: Cable routing for the precise positioning of the cable; easily adjustable length stop for accurately repeated wire stripping

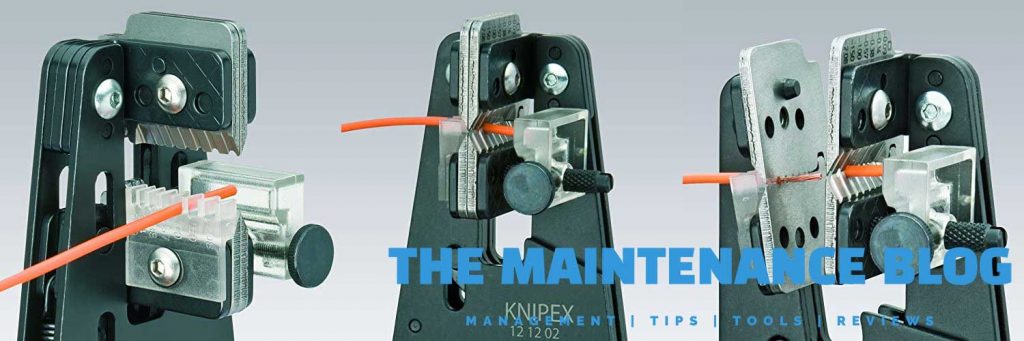

- Four-blade principle: step 1: Two pairs of blades cut into the entire circumference of the hard, challenging insulation with a circular-cut

- Four-blade principle: step 2: One pair of blades (in the left-hand picture) holds the remaining part of the insulation tight, while the second removes the region to be stripped.

- Circular cut for tough, hard insulation materials: Two blades cut right round the PTFE, silicone, Radox, Kapton, and rubber insulation for ideal results.

Download: Knipex Automatic Wire Stripper Product data sheet EN 12 12 02

From the Manufacturer:

Knipex Automatic Wire Stripper 12 12 02 – Precision Wire Strippers for Special Insulation Materials

- Pliers feature burnished handles with multi-component grips.

- A cable guide for precise positioning in the stripping area of the blade.

- Stripping of difficult-to-remove insulating materials such as PTFE, silicone, Radox, Kapton, and rubber; multi-layer too.

- A second pair of blades hold the remaining insulation reliably in place.

Replaceable shaped blade adapted precisely to the respective conductor cross-section. With length stop for constant stripping length during repetitive work. Pliers body: steel; Blade: special tool steel, oil-hardened. This wire stripper is metric; however, when used with dies 12-19-13 (10-20 AWG) and/or 12-19-14 (16-26 AWG) (SOLD SEPARATELY), it can be used on wire according to US specifications.

Two pairs of blades: division of labor for the desired result

The Knipex 12 12 02 wire strippers have been specially developed for tough insulation materials, which need to almost be cut through entirely so that they can be pulled off. Two pairs of blades cut into the entire circumference of the cable insulation. The blades have been shaped and ground so that the cut gets very close to the conductor. After scoring, one of the pairs of blades remains still and secures the insulation that has been cut into. The other pair of blades strip the insulation from the cable.

With adjustable length stop for consistent wire stripping lengths in series production work

Length stop for reproducible stripping results

“The insulation involved here must withstand a great deal, such as being heat-resistant and tough. Cutting insulation like this from the single conductors during stripping is equally challenging. With conventional wire stripping tools, it is difficult and often impossible to achieve a clean wire stripping result. By contrast, with these special wire strippers, even hard to remove insulation is removed accurately and reliably and in a single work step. The model 12 12 02 shown here has an additional insertion aid for precisely positioning the cable on the blade’s wire stripping points. Other Knipex precision wire strippers from this series can be found in the table below.”

Insert cable, press pliers closed – cable is stripped.

The work saved by these wire strippers is immense. After inserting the cable, the entire wire stripping process takes place as if by itself with one press of the hand. Even insulation materials that are difficult to process are reliably removed with precise and, thanks to the length stop, accurate repeat measurements: an advantage for fitters, e.g., in the areas of energy technology, plant, and automotive engineering.

Visit Knipex