Troubleshooting Air Cylinders Pneumatics Part 1

Welcome to “Troubleshooting Air Cylinders, Pneumatics Part 1“. This post will be the first in a series of basic maintenance troubleshooting and training posts. I’m using this website as a platform to test ideas and content that I will later convert to presentations to use as training aids for my maintenance team. I will also share the presentations on this website. This content is not meant to be all-encompassing.

If you want to contribute, message me through the contact page or in the comment section below.

Consider reading our other Knowledge Base articles.

Troubleshooting Air Cylinders

This user-friendly guide, complete with illustrative images, is designed to assist maintenance mechanics and technicians in diagnosing and resolving issues with air cylinders.

See “What is an air cylinder?”

Why is my air cylinder leaking?

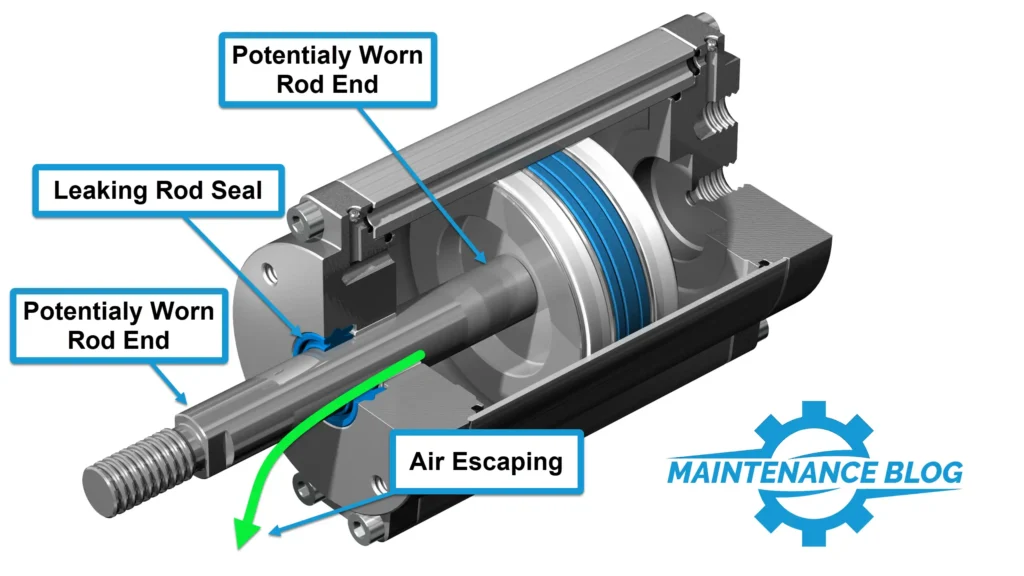

Troubleshooting Air Cylinders: Why is my air cylinder leaking at the rod?

Symptoms of a Leaking Air Cylinder Piston Rod

- A hissing noise from the area where the rod meets the cylinder.

- Small bubbles from air line lubricant or moisture where the rod meets the cylinder.

- Reduced air cylinder retract force. The machine operator might have noticed a regulator air pressure increase adjustment is required to perform a job.

- Position Creep

- Speed Fluctuations

- Black or dirty buildup where the rod meets the cylinder.

Why is my air cylinder leaking around the rod?

Air leaking from the piston typically means the lip, gland, or rod seal is worn or damaged. The damaged seal allows air to escape the cylinder. It’s important to note that the cylinder piston rod is often worn or damaged.

A damaged piston rod will damage the rod seal, allowing air to escape. A worn or damaged rod will also permit air to leak from the rod seal. The first signs of an air cylinder leak failure often occur at the fully extended and retracted positions. The latter being most common.

Can a leaking rod seal be repaired or replaced?

The short answer to the question above is yes. A trained individual using proper tools and care can replace a piston seal on an air cylinder, providing it’s an air cylinder designed to be serviced. However, not all air cylinders are designed to be serviced.

Many small to medium-sized air cylinders are considered disposable by design and replacement cost. Unless your company has air cylinder replacement parts in inventory, obtaining a new air cylinder is almost always faster than ordering replacement parts.

Note: If you buy a repairable cylinder from McMaster Carr, they often stock parts for the same cylinder.

In my career, I have always worked in dusty environments, and when an air cylinder leaks, the piston rod is worn, scored, or otherwise damaged.

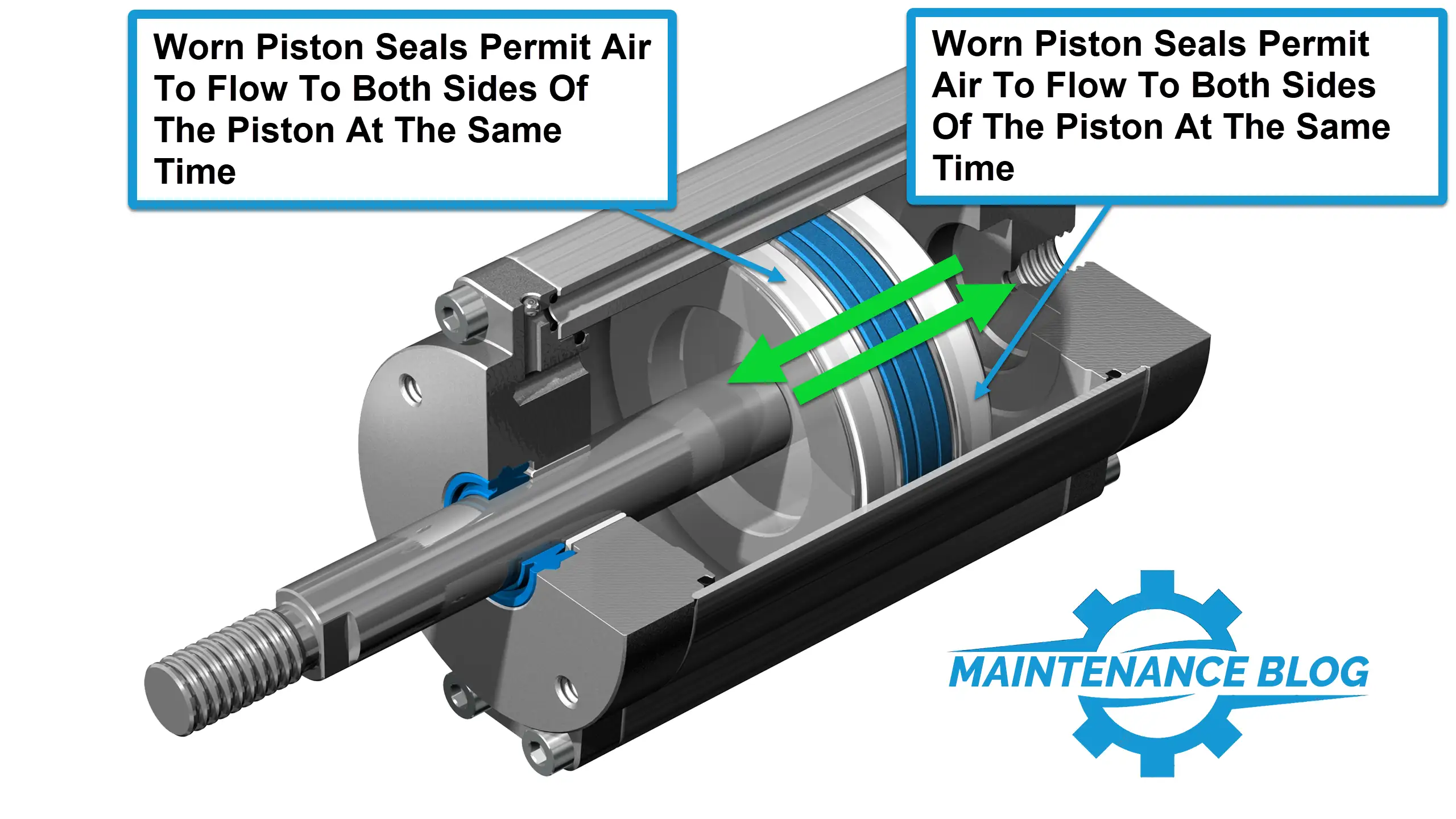

Air Cylinder Piston Seals Leaking

Leaking air cylinder piston seals can be challenging to diagnose for inexperienced or untrained maintenance personnel. The reason is the symptoms do not always directly point to the cause. As you can see in the list below, some symptoms match the symptoms for other pneumatic control problems.

The symptom I see most mechanics diagnose incorrectly is a continuously exhausting solenoid valve. The mechanic’s first thought is, “It’s a bad solenoid valve.” That’s because a solenoid valve that fails to actuate correctly will have some of the same symptoms as failed air cylinder piston seals.

Note: Air cylinders must contain at least one piston seal; many air cylinders have two or more seals.

Symptoms of Leaking Air Cylinder Piston Seals

- Difficult to Control Air Cylinder.

- Position Creep.

- The Air Cylinder Barely Moves.

- Air is constantly exhausting from the Solenoid Valve Exhaust Ports.

- Abnormal Pressure Regulator Operation or Constantly Bleeding Compressed Air

- The Air Cylinder Can’t Apply Proper Force.

- Constantly Bleeding Air from Quick Exhaust Valves and Quick Exhaust Flow Controls

What Causes Air Cylinder Piston Seals to Leak?

- Seal Wear

- Worn or Damaged Rod

- Cylinder Contamination

- Cylinder Age

- Improper Lubrication

- Scored or Damaged Air Cylinder Body or Tube

- Worn Piston Guide

How to Troubleshoot Air Cylinder Piston Seals for Leaks

Testing Double Acting Cylinders

Testing a double-acting air cylinder piston seal for leaks is an easy task. Apply air pressure at one cylinder port while leaving the other cylinder port open. If air flows out of the open port, the seals have failed. Performing the same test in both directions is always a good idea.

Testing Single Acting Cylinders

Testing a single-acting, spring return, air cylinder piston seal for leaks is slightly different. A single-acting only uses air to move the air cylinder in one direction. An internal spring is responsible for the opposing stroke.

Single-acting cylinders only have one pressure supply port. There is typically a small vent on the air cylinder’s spring end. The port will bleed air when an air cylinder has failed piston seals.

Can leaking piston seals be repaired or replaced?

Yes, piston seals can be replaced. The same comments from above apply. If you choose to repair an air cylinder, I suggest you rebuild the complete cylinder. Replace the rod seal, wiper, piston guide, and seals. Festo has a great video on the subject. “How to rebuild an air cylinder.”

Troubleshooting Air Cylinders – Miscellaneous Problems

Below are additional common problems associated with troubleshooting air cylinder malfunctions and performance issues. As time permits, I will add additional images and text.

- Broken or Loose Fittings

- Pinched or Kinked Air Lines

- Leaking Air Lines

- Damaged Cylinder Bodies

- Loose Tie-Rods or End Caps

- Improperly Adjusted Flow Controls

- Blocked or Improperly Adjusted Exhaust Mufflers and Exhaust Flow Controls

- Other Hardware Issues Include Directional Control Valves, Flow Controls, Pressure Regulators, Check Valves and Air Filters.

- Insufficient Air Line Supply Pressure

- Friction of Attached Hardware or Product