PNP vs NPN Sensor Wiring Basics Part 1

PNP vs. NPN

In many industrial environments, maintenance mechanics and technicians encounter a plethora of sensors of various types and technologies. One such sensor, the “3 Wire” proximity sensor, is frequently a common source of confusion for inexperienced team members or members with primarily mechanical skills.

This page is a reference for those inexperienced team members mentioned above and is not meant as a technical paper. This page will focus on the most common PNP, and NPN proximity sensors applications rather than the rare case uses and exceptions. The intent is to keep it simple.

3 Wire PNP and NPN Sensor Types

Most often, the PNP and NPN discussion references “proximity sensors,” In our heads, we envision an 8mm or 12mm cylindrical 3-wire tubular proximity sensor. Other common industrial sensors work similarly or, more importantly, get wired the same way.

3 Wire Sensor Examples

- Proximity Sensors

- Cylinder Position Sensors

- Capacitive Sensors

- Photoelectric Sensors**

- Laser Sensors**

*Note: Some 3 wire sensors have a white fourth wire that is complimentary output to the black wire.

**Note: Some more intelligent sensors have additional functionality and wires (Teach/LearnModes). Consult the manufacturer’s documentation.

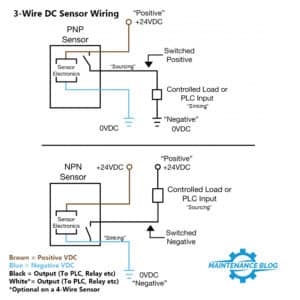

PNP vs NPN Sensor Wiring Basics

PNP and NPN sensors use the same wire colors and labeling convention. The difference is how they electrically interact with the load, and the load is a device like a relay or PLC input.

- Brown is the positive dc voltage, typically +24VDC

- Blue is the negative dc voltage, typically -24VDC

- Black is the output to an external load. This will be either “Normally Open” or “Normally Closed.”

- White, if applicable, is the complementary output of the black wire. Example: If the black wire is “Normally Open,” the white wire would be “Normally Closed.”

PNP vs NPN Frequently Asked Questions

PNP vs. NPN Interchangeability

- Can I use an NPN sensor instead of a PNP? – Maybe, it depends on the application. Yes – If the sensor directly controls a small inductive load like an indicator light or low-current relay, NPN or PNP can be used. No – If the sensor is wired to the input of PLC, process meter, or some other solid-state device

- Can I use a PNP sensor instead of an NPN? – Maybe, it depends on the application. Yes – If the sensor directly controls a small inductive load like an indicator light or low-current relay, PNP or NPN can be used. No – If the sensor is wired to the input of PLC, process meter, or some other solid-state device

- Can I use an NPN sensor instead of a PNP sensor on a PLC input? – No

- Can I use a PNP sensor instead of an NPN sensor on a PLC input? – No

Note: Some PLC input cards are PNP or NPN input type selectable. However, typically the entire module needs to be either PNP or NPN. Mixing types is not permitted and may damage the plc.

What’s the Difference Between PNP and NPN Sensors?

PNP = “Positive Switching” or “Sourcing” A “PNP” sensor switches the positive dc signal voltage(+24VDC).

NPN = “Negative Switching” or “Sinking” A “NPN” sensor switches the negative dc signal voltage (-24VDC).

The black wire of both PNP and NPN sensors is the output. If the sensor includes a fourth white wire, that is also an output wire that is typically in the opposite switch state as the black wire.

Note: The easiest way to test whether a 3-wire sensor is PNP or NPN is to use a sensor test box such as the Banner DBQ5 Proximity Sensor Tester.

PNP vs. NPN Sensor Wiring Examples:

Downloads:

Note: The downloads will continue to be updated as the article expands. If you spot any errors, please comment below.

- PNP vs NPN Basics and Wiring Schematics Part 1 – Word Format

- PNP vs NPN Basics and Wiring Schematics Part 1 – Adobe Acrobat Format

Helpful Resources:

- Balluff Innovating Automation Blog Automation Insights is sponsored and administered by Balluff, Inc., the US subsidiary of Balluff GmbH